Variety Types safety Carbide Inserts Cnmg/Dnmg/Tnmg/Vnmg/Wnmg for Turning

Basic Info

| Model NO. | FK-S |

| Customized | Customized |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Grades | K10/K20/K30/K40/Yl10.2/Yg6/Yg6X/Yg8/Yg10X/Yl10.2 |

| Delivery Time | 1-15days |

| Usage | CNC Lathe Machine |

| Place of Birth | Chengdu China |

| Transport Package | Carton |

| Origin | China |

| Condition | New |

| Material | Tungsten Carbide |

| Wc+Co Powder | 100% Virgin Material |

| Surface Finishing | Finishing and Semi Finishing |

| Hardness | 83-93hra |

| Advantage | Wear Resistance |

| Trademark | Fengke |

| Specification | TNMG160408 |

| HS Code | 8208101900 |

Product Description

Variety Types Safty Carbide Inserts CNMG/DNMG/TNMG/VNMG/WNMG For Turning

1.Coated Carbide(CVD)

Applicable from low to high speed cutting and from finishing to roughin.

Stable cutting is achieved due to the superior toughness and crack resistance.

Cutting times are reduced due to good chip control from effective chipbreakers.

Achieving superior processing efficiency in the field of a wide range of steel/casting Parts processing.

GR5525 : suitable for low speed machining of steel part

GR5535 : suitable for high speed machining of steel part

GR5115 : suitable for hihg speed machining of cast iron part

2.Coated Carbide(PVD)

Good for low to high speeds and finishing to heavy roughing cutting.

Stable cutting with excellent toughness.

Smooth fine surface of PVD coated carbide provides good surface finish and high.

Achieved high reliability in the unstable processing field of stainless steel

GR930 : suitable for high speed machining of stainless steel.

How to use CNC Carbide Insert?

1. The guide of the applications of tungsten carbide insert (cemented carbide insert):

1st: the structure of tungsten carbide tips tools should be tough enough.

2nd: cemented carbide tips should be strongly fixed securly.

3rd: before installing of the tungsten carbide tips to the tool holders,the tips and tool holder must be checked,an initial check must be done to ensure that there is no serious bending on the support surface of the tips,there shall be no serious carbulization on the welding surface of the tips,and at the same time,the contaminants on the surface of the tips and in the flutes of the tool holers must be eliminated to ensure the quality of a secure welding.

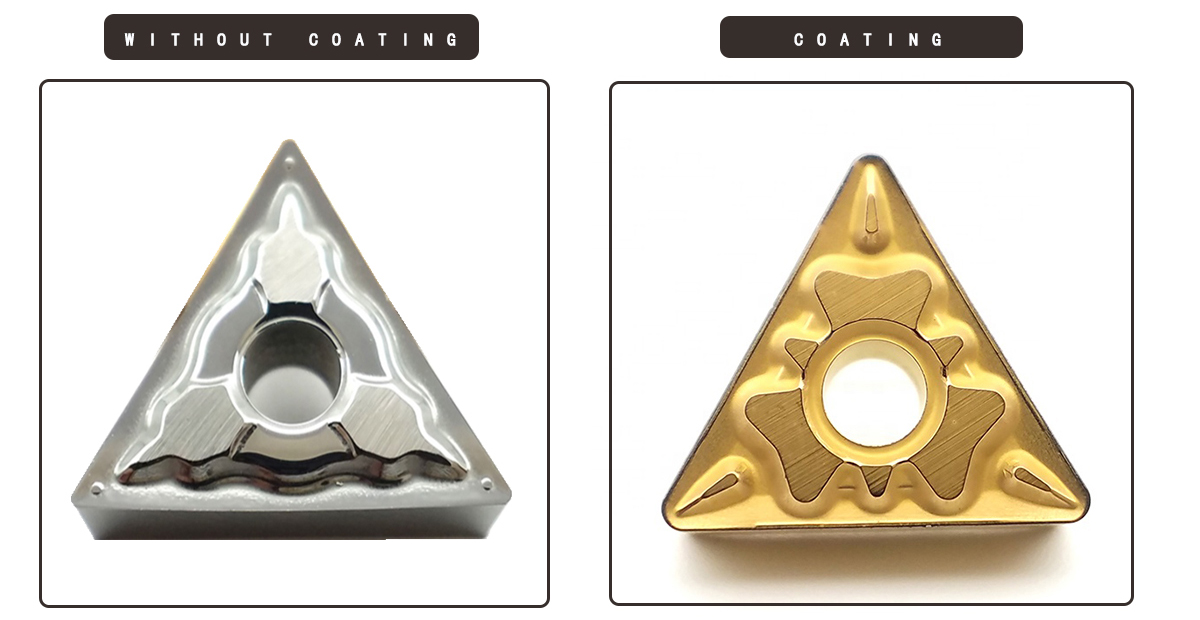

4th. CNC Insert,Coating and without Coating are available:

What are the Advantage of Carbide Insert ?

1. Made in 100% virgin carbide powder, excellent wear resistance and toughness;

2. High performance CVD coating, with super hard and smooth surface;

3. Performed 100% inspection, under ISO9001:2015 quality system control;

4. Professional chip-breaker design, provides perfect cutting performance;

5. Precise dimension, high accuracy;

6. Super long and consistent tool life;

What is the Application?

1. Our tungsten carbide CNC inserts are made from 100% virgin raw materials, under HIP processing. They have excellent wear resistance and hardness, widely used in turning, , grooving, cutting tools for MENTAL

2.For steel, stainless steel, Aluminum processing

What is the Specification?

We offer OEM (Original Equipment Manufacturer) supplied carbide insert and cutters which is available in round, square, radius, and diamond shaped that fit many of the commercial woodturning tools.

|

Product Name

|

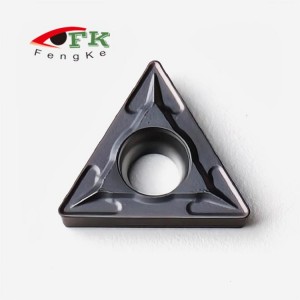

TNMG160408 carbide inserts tungsten cnc inserts turning inserts cutting tool

|

|

Material

|

steel/stainless steel/Cast iron

|

|

Coating

|

CVD/PVD

|

|

Standard

|

ISO

|

|

Model

|

TNMG160404 160408 160412 220404 220408 220412

|

|

Suitable for

|

Turning tool MTENN MTFNR/L MTJNR/L MTGNR/L PTFNR/L

|

|

Used

|

CNC Lathe machinery

|

** We could produce carbide blades according to your technical drawings.

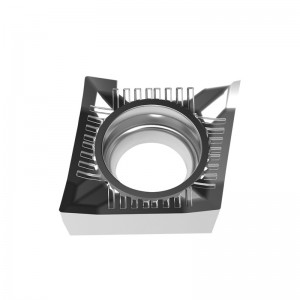

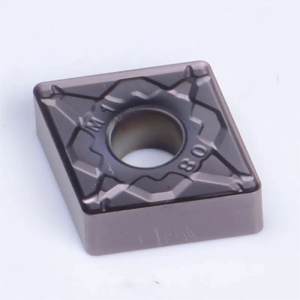

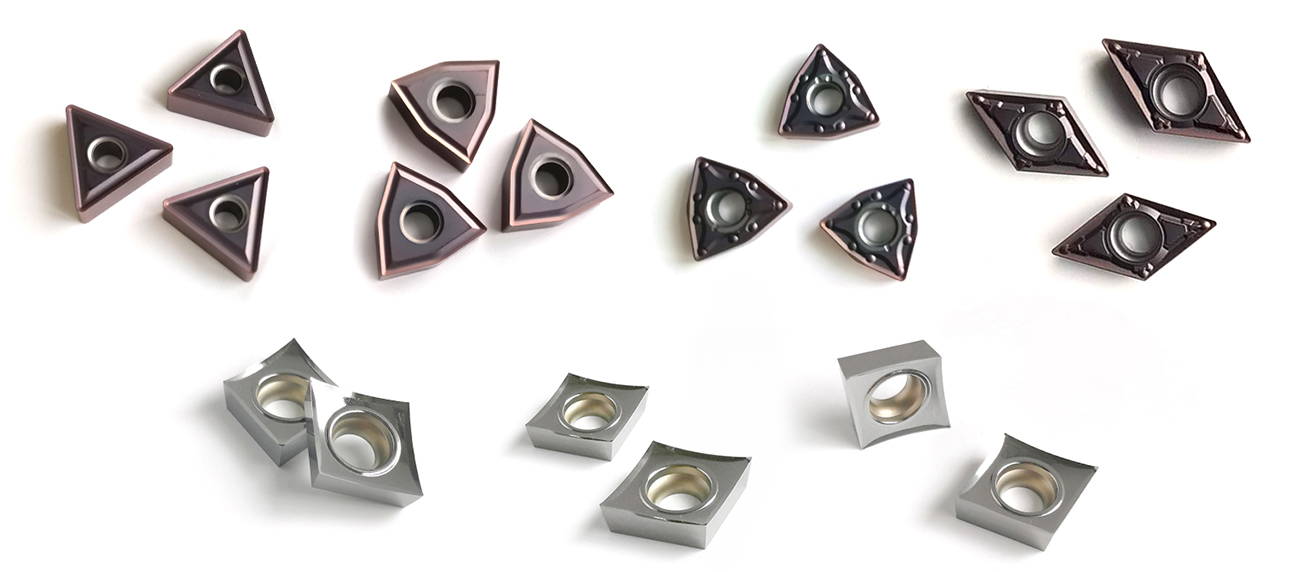

What Does your INDEXABLE CARBIDE INSERT Look Like?

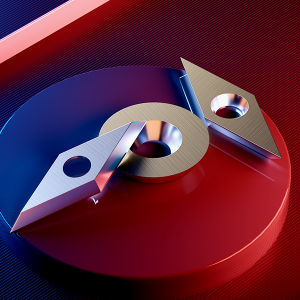

For more reference products:

Why Choose Us?

3:We take great efforts to increase commodity types rather than quantitiy to promote the flexibility of competing in the worldmarket. Above all , our client's demands are always the first to be considered.

4:Skillful workers and advanced euquipments can make every of your size possible.

5:For standard size, we always have stocks.

How to Packing ?

| Delivery | |

| Shipping ways | Air transportation,Sea transportation,Land transportation,Express tec. |

| Shipping Deatails | We can choose fastest and chheapest shipping way for you.If you have any question regarding packing,payment terms and delivery time,pls feel free too contact us. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are Factory with 20years of production experience.

Q2: Where is your factory?

We are located in Chengdu city, Sichuan province where is half hour away from Shuangliu airport by Car.

Q3: Is the competitive price of planer blade?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Is the top quality?

Yes. All products will be tested before bulk processing, and we will check the physi-cal properties, shape and

tolerance for ensuring qualified products before shipping.

Q5: What's your delivery time ?

For the normal type which we have mold it takes 5-14 days after receiving the advance payment.

For the non standard which we do not have mold it takes 14-30 days after receiving the advance payment.

Q6: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample (less than 1Kg) for free charge