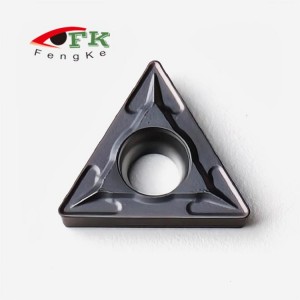

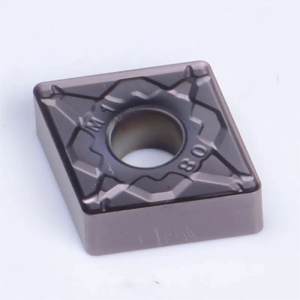

Fengke CNC Carbide Inserts VBGT/VCGT160404/160402/160408-AK

Variety Types Safty Carbide Inserts CNMG/DNMG/TNMG/VNMG/WNMG For Turning

1.Coated Carbide(CVD)

Applicable from low to high speed cutting and from finishing to roughin.

Stable cutting is achieved due to the superior toughness and crack resistance.

Cutting times are reduced due to good chip control from effective chipbreakers.

Achieving superior processing efficiency in the field of a wide range of steel/casting Parts processing.

GR5525 : suitable for low speed machining of steel part

GR5535 : suitable for high speed machining of steel part

GR5115 : suitable for hihg speed machining of cast iron part

2.Coated Carbide(PVD)

Good for low to high speeds and finishing to heavy roughing cutting.

Stable cutting with excellent toughness.

Smooth fine surface of PVD coated carbide provides good surface finish and high.

Achieved high reliability in the unstable processing field of stainless steel

GR930 : suitable for high speed machining of stainless steel.

Basic Info

| Model NO. | FK-S |

| Customized | Customized |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Grades | K10/K20/K30/K40/Yl10.2/Yg6/Yg6X/Yg8/Yg10X/Yl10.2 |

| Delivery Time | 1-15days |

| Usage | CNC Lathe Machine |

| Place of Birth | Chengdu China |

| Transport Package | Carton |

| Origin | China |

| Condition | New |

| Material | Tungsten Carbide |

| Wc+Co Powder | 100% Virgin Material |

| Surface Finishing | Finishing and Semi Finishing |

| Hardness | 83-93hra |

| Advantage | Wear Resistance |

| Trademark | Fengke |

| Specification | TNMG160408 |

| HS Code | 8208101900 |

Product Description

How to use CNC Carbide Insert?

1. The guide of the applications of tungsten carbide insert (cemented carbide insert):

1st: the structure of tungsten carbide tips tools should be tough enough.

2nd: cemented carbide tips should be strongly fixed securly.

3rd: before installing of the tungsten carbide tips to the tool holders,the tips and tool holder must be checked,an initial check must be done to ensure that there is no serious bending on the support surface of the tips,there shall be no serious carbulization on the welding surface of the tips,and at the same time,the contaminants on the surface of the tips and in the flutes of the tool holers must be eliminated to ensure the quality of a secure welding.

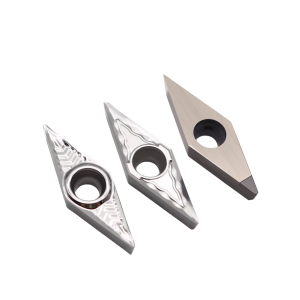

4th. CNC Insert,Coating and without Coating are available:

What are the Advantage of Carbide Insert ?

1. Made in 100% virgin carbide powder, excellent wear resistance and toughness;

2. High performance CVD coating, with super hard and smooth surface;

3. Performed 100% inspection, under ISO9001:2015 quality system control;

4. Professional chip-breaker design, provides perfect cutting performance;

5. Precise dimension, high accuracy;

6. Super long and consistent tool life;

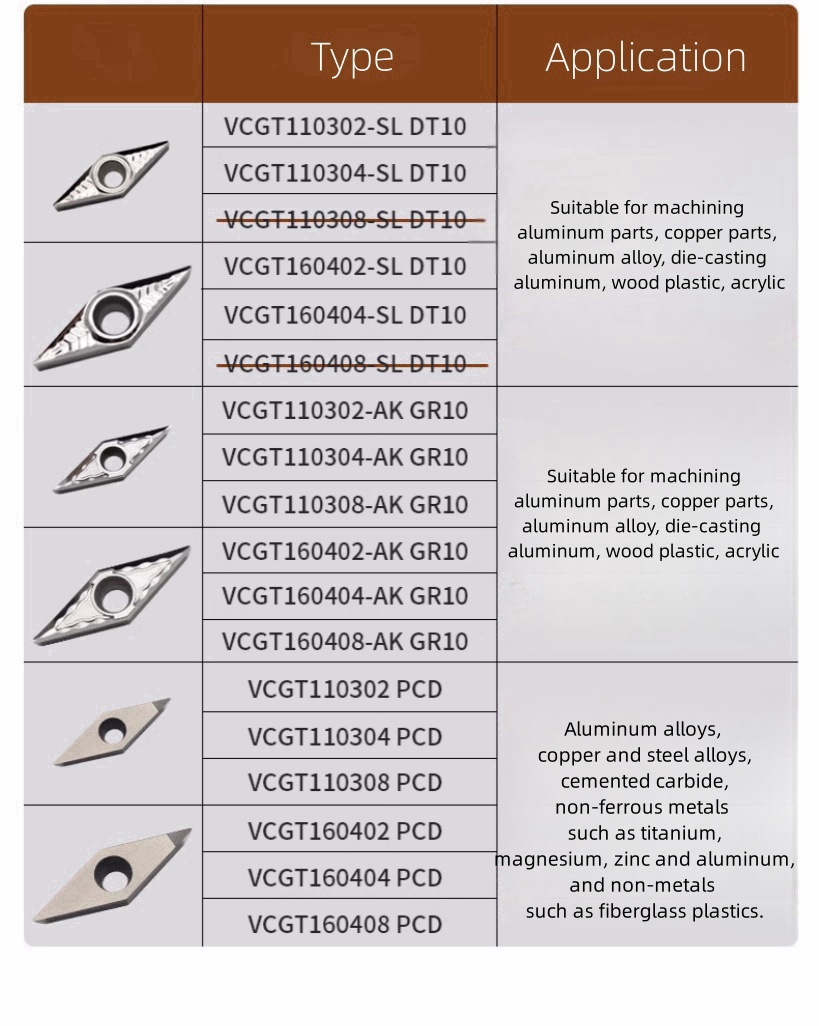

What is the Application?

1. Our tungsten carbide CNC inserts are made from 100% virgin raw materials, under HIP processing. They have excellent wear resistance and hardness, widely used in turning, , grooving, cutting tools for MENTAL

2.For steel, stainless steel, Aluminum processing