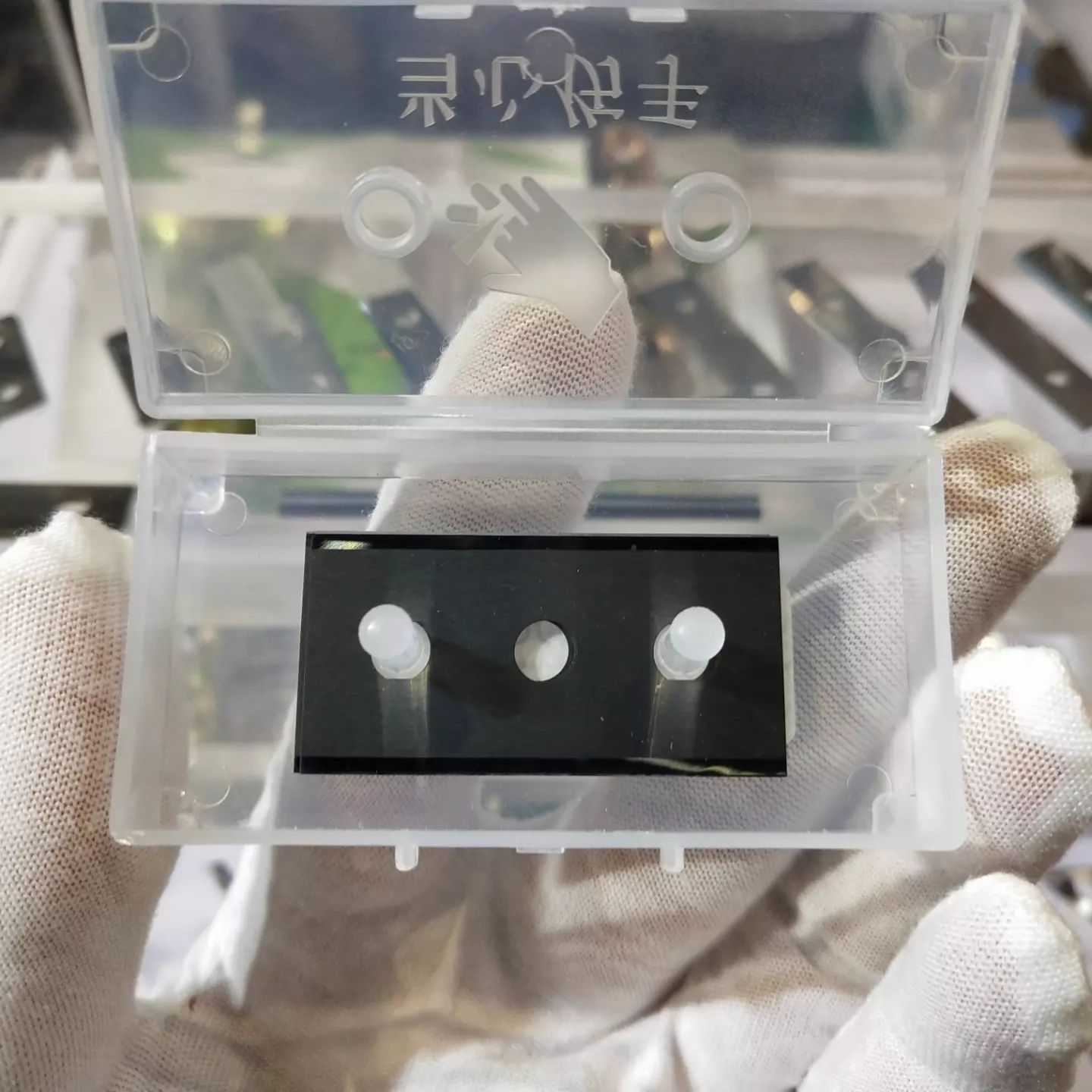

When it comes to efficient and precise film cutting, not all blades are created equal. In the world of packaging and wrapping materials, the 3 hole razor blade stands out as a top choice for professionals seeking clean, accurate cuts. In this article, we'll delve into the benefits of 3 hole razor blades for cutting film and explore why they are the go-to tool for those who demand perfection in their packaging processes.

The Precision of 3 Hole Razor Blades:

- Reduced Friction: The three holes strategically placed along the blade serve a critical purpose. They reduce friction as the blade moves through the film, ensuring a smooth and uninterrupted cutting experience. This reduction in friction not only prolongs the blade's lifespan but also guarantees clean cuts without tearing or jagged edges.

- Clean and Neat Cuts: One of the primary advantages of using 3 hole razor blades for cutting film is the precision they offer. Film materials can be delicate, and a clean, neat cut is essential to maintain the integrity of the product being wrapped. With these blades, you can say goodbye to uneven and messy edges.

Versatility in Film Cutting: 3 hole razor blades are not limited to one type of film. They are versatile tools that can efficiently cut through a wide range of materials, including plastic wrap, shrink wrap, and various packaging films. This versatility makes them an ideal choice for industries that deal with diverse packaging needs.

Longevity and Cost-Efficiency: Investing in high-quality 3 hole razor blades pays off in the long run. Their durability ensures a longer lifespan compared to standard blades, reducing the frequency of replacements. This not only saves you money but also minimizes downtime, keeping your packaging operations running smoothly.

Safety Considerations: Safety is paramount when working with razor blades, and 3 hole designs take this into account. Some models come with safety features such as blade guards or retractable mechanisms to protect users from accidental cuts. Prioritizing safety in the workplace is crucial, and these blades can help mitigate potential risks.

Conclusion: In the world of film cutting, precision matters. 3 hole razor blades have proven time and again to be the choice of professionals for their ability to deliver clean, neat cuts while reducing friction and ensuring versatility. Their durability and cost-efficiency make them a wise investment for businesses of all sizes.

If you're in the packaging industry or any field that involves cutting film materials, consider upgrading to 3 hole razor blades. Your packaging process will benefit from improved efficiency and higher-quality results, ultimately leading to increased customer satisfaction and reduced operational costs. So, don't settle for less when you can have precision and perfection with 3 hole razor blades.

Post time: Sep-22-2023