When it comes to creating seamless and sturdy finger joints in woodworking projects, the choice of a finger joint shaper cutter plays a crucial role. With a myriad of options available, selecting the right cutter can be a daunting task. Fear not! In this comprehensive guide, we will walk you through the key factors to consider when choosing a finger joint shaper cutter. By the end, you’ll have the knowledge and confidence to make an informed decision that aligns with your woodworking needs and aspirations.

Section 1: Understand Your Woodworking Requirements

1.1 Project Scope: Consider the scale and scope of your woodworking projects. Are you primarily focused on small-scale projects like boxes and drawers, or are you working on larger furniture or cabinetry pieces? Identifying your project requirements will help determine the appropriate finger joint shaper cutter size and capabilities needed.

1.2 Wood Type and Thickness: Different wood types have varying densities and characteristics. Determine the type of wood you commonly work with and assess its thickness. Some finger joint shaper cutters may be better suited for hardwoods, while others are designed to handle softer woods or composite materials.

Section 2: Key Features to Look for

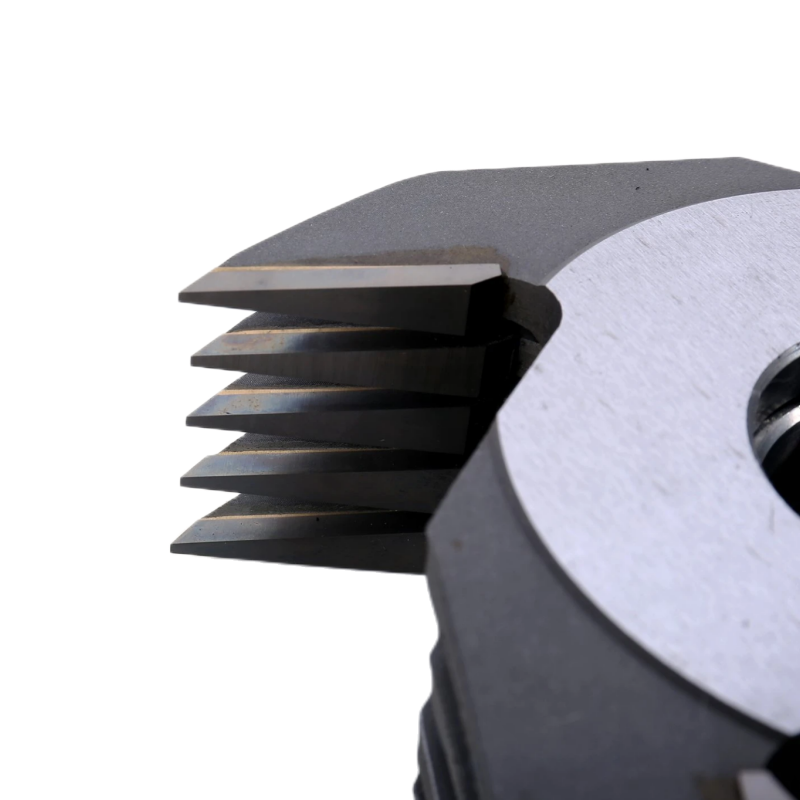

2.1 Cutter Material: The material of the cutter plays a vital role in its performance and durability. High-speed steel (HSS) and carbide-tipped cutters are popular choices. HSS cutters offer a balance of affordability and longevity, while carbide-tipped cutters provide exceptional durability and wear resistance, albeit at a higher cost.

2.2 Cutter Design and Configuration: Evaluate the cutter’s design and configuration to ensure it meets your specific joint requirements. Consider the number of blades or cutters, their arrangement, and the resulting finger size and spacing. The cutter design should enable precise and uniform cuts for seamless joint assembly.

2.3 Compatibility with Shaper Machine: Verify that the finger joint shaper cutter is compatible with your shaper machine. Check the spindle size and ensure it matches your machine’s specifications. Additionally, consider the cutter’s overall dimensions and whether it will fit comfortably within your shaper’s cutting capacity.

Section 3: Quality and Reliability

3.1 Brand Reputation: Research and identify reputable brands known for their quality woodworking tools. Look for brands that have a strong track record in manufacturing finger joint shaper cutters and receive positive reviews from professionals and hobbyists alike.

3.2 Customer Reviews and Ratings: Read customer reviews and ratings of the finger joint shaper cutters you are considering. Pay attention to feedback regarding the cutter’s performance, durability, and overall user experience. This will provide valuable insights into the cutter’s real-world performance.

3.3 Warranty and Customer Support: Check if the finger joint shaper cutter comes with a warranty, as this demonstrates the manufacturer’s confidence in their product. Additionally, consider the availability of reliable customer support in case you encounter any issues or require assistance.

Conclusion:

Selecting the right finger joint shaper cutter is a crucial step towards achieving precise and durable finger joints in your woodworking projects. By understanding your woodworking requirements, evaluating key features, and considering quality and reliability factors, you can make an informed decision. Remember to prioritize the compatibility of the cutter with your shaper machine and choose a trusted brand that aligns with your needs. Armed with this knowledge, you are now equipped to embark on your woodworking journey with confidence, knowing that you have chosen the perfect finger joint shaper cutter for your craft.

Post time: May-19-2023