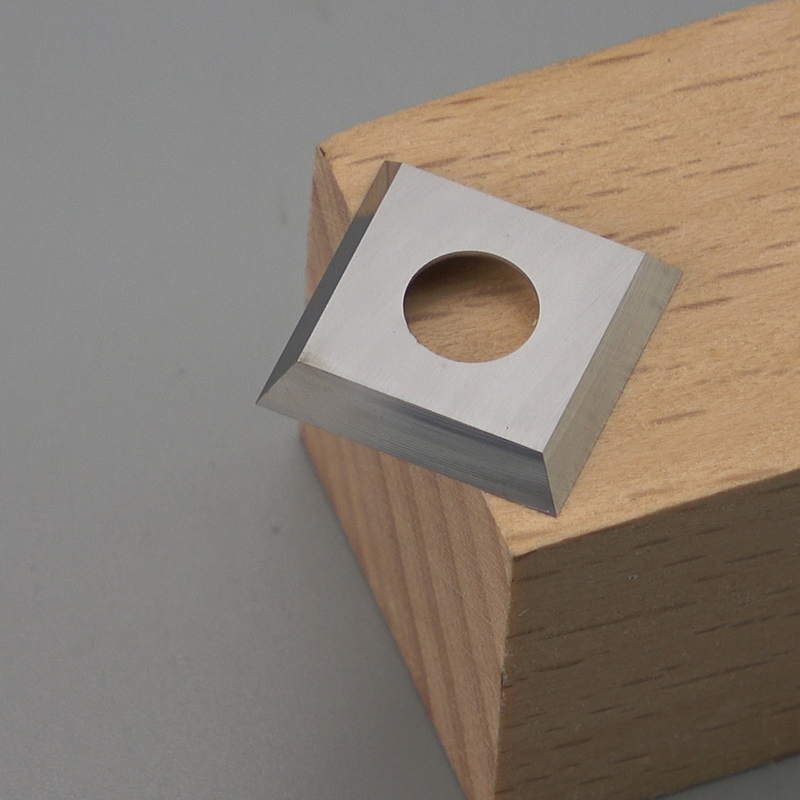

Carbide inserts are made from high quality carbides and are extremely durable. They are also very sharp and easy to sharpen.

This makes them ideal for wood cutting.

Carbide inserts are used for cutting hard materials such as metal, stone, glass, plastic, ceramic, and more. These inserts are usually made from tungsten carbide (WC) or titanium carbide (TiC). Tungsten carbide is harder than steel and has excellent wear resistance. It is also resistant to heat and chemicals. Titanium carbide is even harder than tungsten carbide and is often used for machining stainless steel.

Woodworking tools are essential for anyone who wants to create beautiful pieces of furniture. The most common types of woodworking tools include saws, drills, sanders, clamps, and jigsaws. A drill press is a type of power tool that allows you to use a drill bit at different speeds and depths. You can use a drill press to cut holes into wood, metal, and other materials. Sandpaper is a material that removes surface scratches and imperfections from wood. Clamps hold two objects together while you work. Jigsaws are used to cut the wood into smaller pieces.

The insert will last longer than other blades.

Carbide inserts are much sharper than regular woodcutting blades. This means that they cut through material faster and with less effort. Because they are so sharp, they do not need to be replaced as frequently. In addition, because they are made from carbide, they are able to withstand higher temperatures than regular blades. As a result, they can be used to cut through materials that would melt or burn a regular blade.

You won't have to sharpen it as often.

If you use a carbide insert, you will only need to sharpen it once every few months. Regular wood cutting blades require constant sharpening. This makes them more expensive to replace.

Carbide inserts are used in power tools such as circular saws, table saws, and router tables. The carbide blade is attached to a steel base plate which is then mounted into the tool's motor housing. Carbide blades last longer than regular blades because they are harder and sharper.

It's easier to use.

Carbide inserts are much easier to use than regular wood cutting blades. You won't have to worry about getting your hands dirty with sawdust. And because they are so sharp, you'll spend less time honing them.

The best thing about carbide inserts is that they are easy to sharpen. If you're new to using them, you can get started right away. Just follow the manufacturer's instructions. Once you've got the hang of it, you'll be able to cut wood quickly and easily.

It's safer to use.

Carbide inserts are more efficient than steel blades. Because they are harder than steel, they will last longer and cut through material faster. This means you'll spend less time sharpening them.

The best thing about carbide inserts is that they won't dull as quickly as steel blades. Steel blades tend to get duller after each use because they're softer than carbide. That means you'll have to sharpen them more often. If you want to save some time, buy a set of carbide inserts instead of buying individual blades. You can find carbide inserts at most hardware stores.

Post time: Dec-09-2022