High Efficiency Cemented Carbide Inserts Cutters For Wood Turning and DIY

What is the Carbide Woodturning Tool?

Long wearing tungsten carbide inserts are offered in dozens of standard sizes with two or four wear edges, this carbide cutters are the perfect choice for running woods such as Teak, Hard Maple,Ipe and MDF.

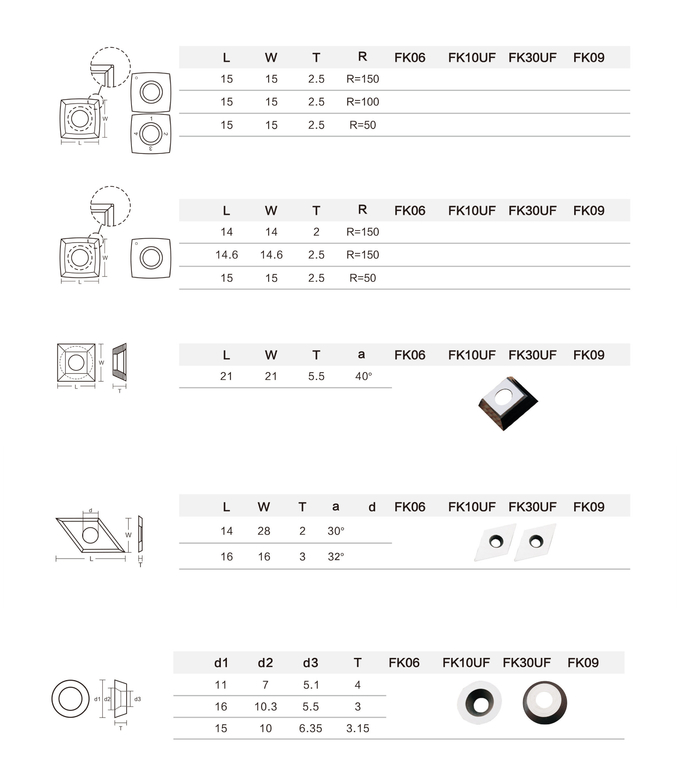

We provide different types of tungsten carbide inserts for woodturning, inculding standard types, such as squared inserts, roud inserts, rectangle planer inserts, etc., we also can produce the woodworking carbide parts based on your designs.

What Does your Woodturning Inserts Look Like?

What is the Feature of Carbide Woodturning Inserts?

1. Replacement cutter to reduce the frequency of replacing blades with longest working life.

2. Environmental protection, high efficiency, energy saving, recyclable.

3. Complete specifications for choose in stock.

4. Easy to operate and easy to use.

What is the Specification of Woodturning Inserts?

What is the Advantage of Woodturning Inserts?

1. Longevity. A single set of carbide inserts will outlast a conventional knife set by approximately

40 times. That’s because each insert is made of advanced quality of carbide raw material and

has four cutting edges. Each edge will last up to 10 times longer than a typical HSS knife-edge.

2. Jointing manufactured materials. Carbide inserts allow you to joint manufactured materials,

such as melamine and MDF.

3. Enjoy quick changes. With carbide inserts, knife changes are no longer such an onerous task.

What is the Application?

They fit many rebate blocks, slotting tooling, spiral planing heads and other spindle tooling. Super sharp, they will cut an accurate scribe in all timbers.

How to Use Carbide Woodturning Inserts?

1: Position the tool rest as close to the work as possible so the carbide cutter is at the lathe center line.

2: Place the tool on the tool rest with the tool shaft parallel with the floor.

3: While securely holding the tool to keep the flat bottom in constant contact with the tool rest slowly plunge the carbide cutter into the work.

What Should We Pay attention to?

1: When you are on the working, please remember to protect your eyes from flying debris!

2: Please don’t let children touch it.

3: Prevent moisture.